SolidCAM 2023 SP3 HF5 Multilingual for SolidWorks 2018-2025 (x64)

Medizin inklusive/Crack

Medicine included/crack

Size: 6.41 GB

format:Rar/exe/iso

Languages: Multilanguage, English, German.....

Compatibility: Windows 10, 11 [64-bits]

SolidCAM is a new generation CAD/CAM system developed by the Israeli company SolidCAM Ltd (Official distributor in Russia – Consistent Software). This system is a comprehensive solution for the automation of metalworking production. Using a wide range of SolidCAM strategies for turning, milling, turning-milling and electrical discharge machining, a technologist can quickly prepare the necessary set of control programs for mechanical processing of a product.

SolidCAM functionality

2.5-axis milling

SolidCAM provides high efficiency and accuracy of 2.5-axis milling of parts. Various strategies for processing such elements as contour, selection (with islands) and groove are supported, as well as various types of hole processing: drilling, countersinking, thread cutting, etc. The system has a wide range of capabilities for 2.5-axis processing of analytical surfaces.

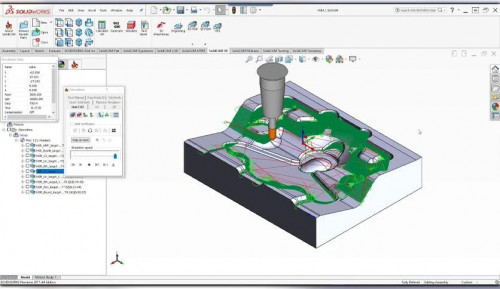

SolidCAM 3-axis milling

offers a wide range of tools that can be effectively used for processing products with complex geometry (dies, press forms) and prismatic parts. A 3D surface or solid model is used as geometry for 3-axis machining. The system supports various types of roughing and finishing strategies, such as raster machining with a specified or automatically determined raster angle, equidistant machining, projection machining, waterline machining, etc.

In addition to the already listed capabilities of 2.5- and 3-coordinate machining, SolidCAM offers tools for identifying and refining areas that were not processed in previous transitions. It is possible to create a database of typical technological processes. Once created, such a parameterized technological process can be repeatedly used in the future, which significantly reduces the time of production preparation, increases the reliability of the developed programs, unifies the style of technological developments, guarantees the use of only optimal machining technologies and ensures the independence of production from the human factor. The absence of cuts is guaranteed by the presence of control and visualization tools for mechanical processing.

Multi-axis machining

SolidCAM offers various tools for creating control programs for multi-axis machining on 4- and 5-axis machining centers. The model is installed in a user-defined machining plane, after which the system automatically calculates all the necessary offset and rotation parameters for the part zero. As a result, the preparatory and final transition time is significantly reduced and the machining accuracy is increased.

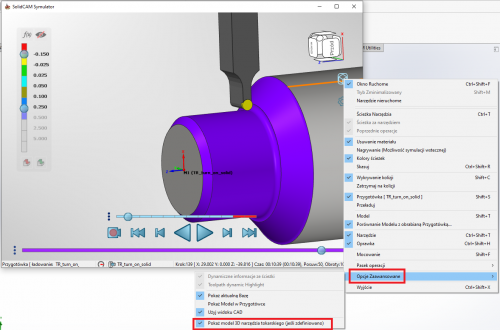

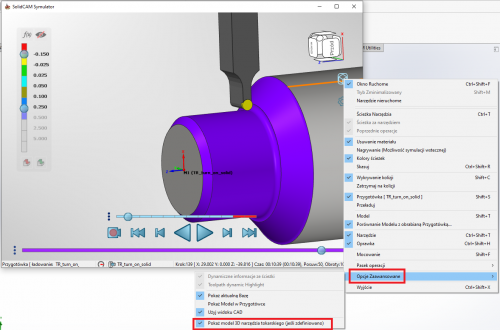

Turning and turn-milling processing

SolidCAM has a wide range of functions for automating the creation of control programs for turning and turn-milling processing. SolidCAM supports various types of tools, which allows for efficient longitudinal turning, end trimming, groove processing, etc. In addition, SolidCAM allows for automatic roughing and finishing of complex contours. Support for rotating tools allows for milling and drilling transitions on machining centers.

Electrical Discharge Machining

SolidCAM's set of wire electrical discharge machining strategies enables machining of external and internal contours with constant and variable inclination angles. 4-axis machining is possible. A special algorithm prevents the material from falling. SolidCAM provides the user with the means to control the physical parameters of machining along the entire wire path.

System requirements : pre-installed SolidWorks 2018-2025

Screenshots

Download

all hosters are compatible - alle Hoster sind kompatibel

Code:

https://rapidgator.net/file/3bc458dd4ee4175daa9951f90c25a64b

https://rapidgator.net/file/cd9cfdc7320b541b3df4cf40d41af3f5

https://rapidgator.net/file/9004a0410e14743e4b795aad08c2af25

https://rapidgator.net/file/8f7637eca7d0147e0868973fb93e2861

https://rapidgator.net/file/6dec5552916adb7754cd3929fcc257de

https://rapidgator.net/file/88997f7d543ad8d6d23125b71e3d8c6e

https://rapidgator.net/file/51ae1cf58d1f99a1dc93d27d1b25e82b

https://nitroflare.com/view/B4F880C5A34ECDA

https://nitroflare.com/view/82C5590CF03E1AF

https://nitroflare.com/view/8CA14D7DB372CA5

https://nitroflare.com/view/0345DD8678FB32F

https://nitroflare.com/view/1803D82F89F5B07

https://nitroflare.com/view/DCFBFB4C217D2B0

https://nitroflare.com/view/BEBE4C14DBEF71C

Zitieren

Zitieren